Single Crystal Si Components

We manufacture Single Crystal Si components for the semiconductor and defense markets and our success is possible due to our proprietary and patented processes specifically developed for Single Crystal Si.

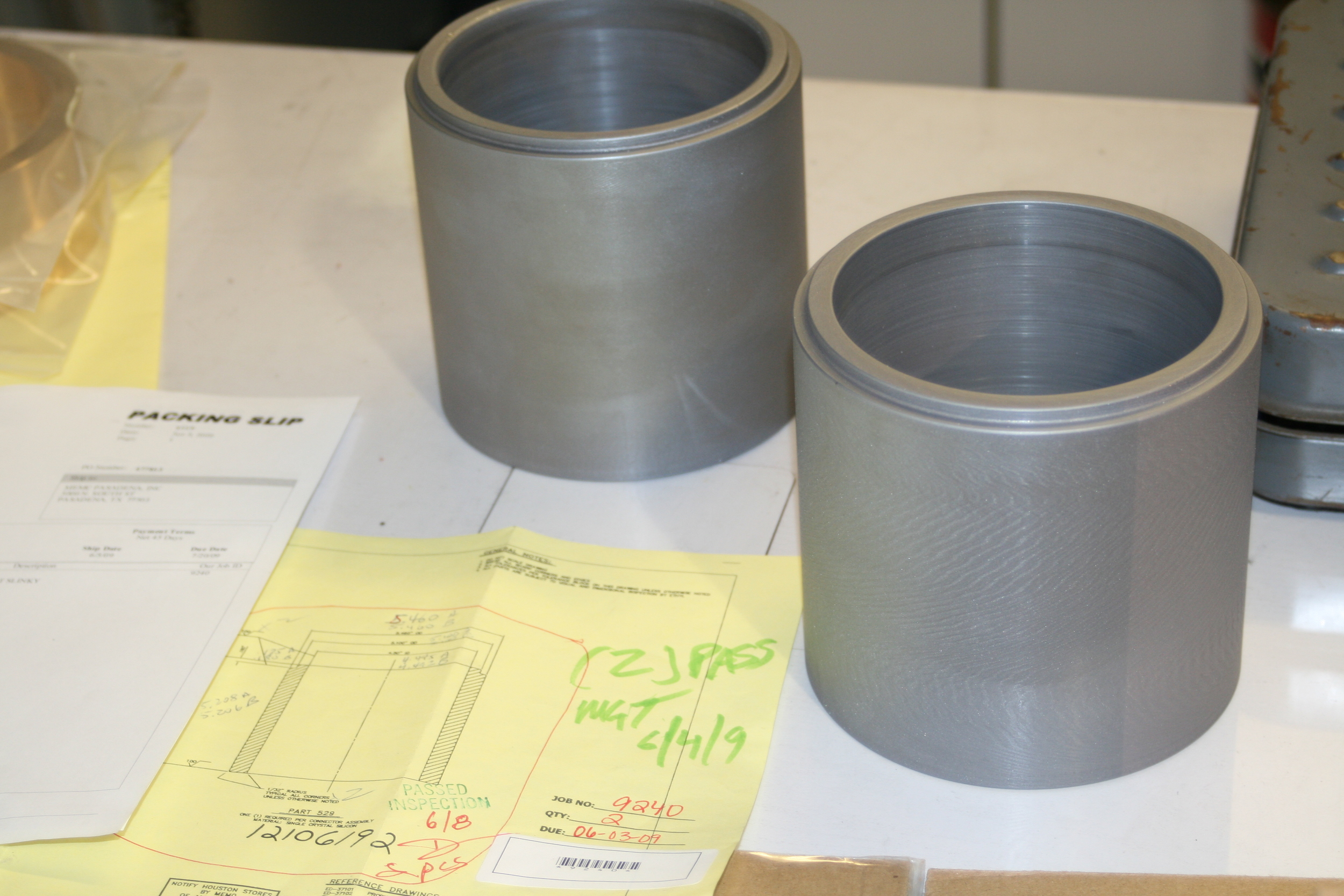

Semiconductor Replacement Parts

We first fabricated silicon components in 1988 when a local semiconductor company requested replacement parts made from silicon. This customer required parts from Single Crystal Si for their silicon-pulling equipment in order to maintain purity.

As a result of our expertise in the semiconductor area, we developed a reputation as a premier manufacturer of Single Crystal Si, especially complex shapes with very close tolerances. In 1993, a Prime Contractor for the US Government contracted us to build a sample Single Crystal Si optical device. The success of that project led to a follow-on program and the expansion of the our business into a new direction.

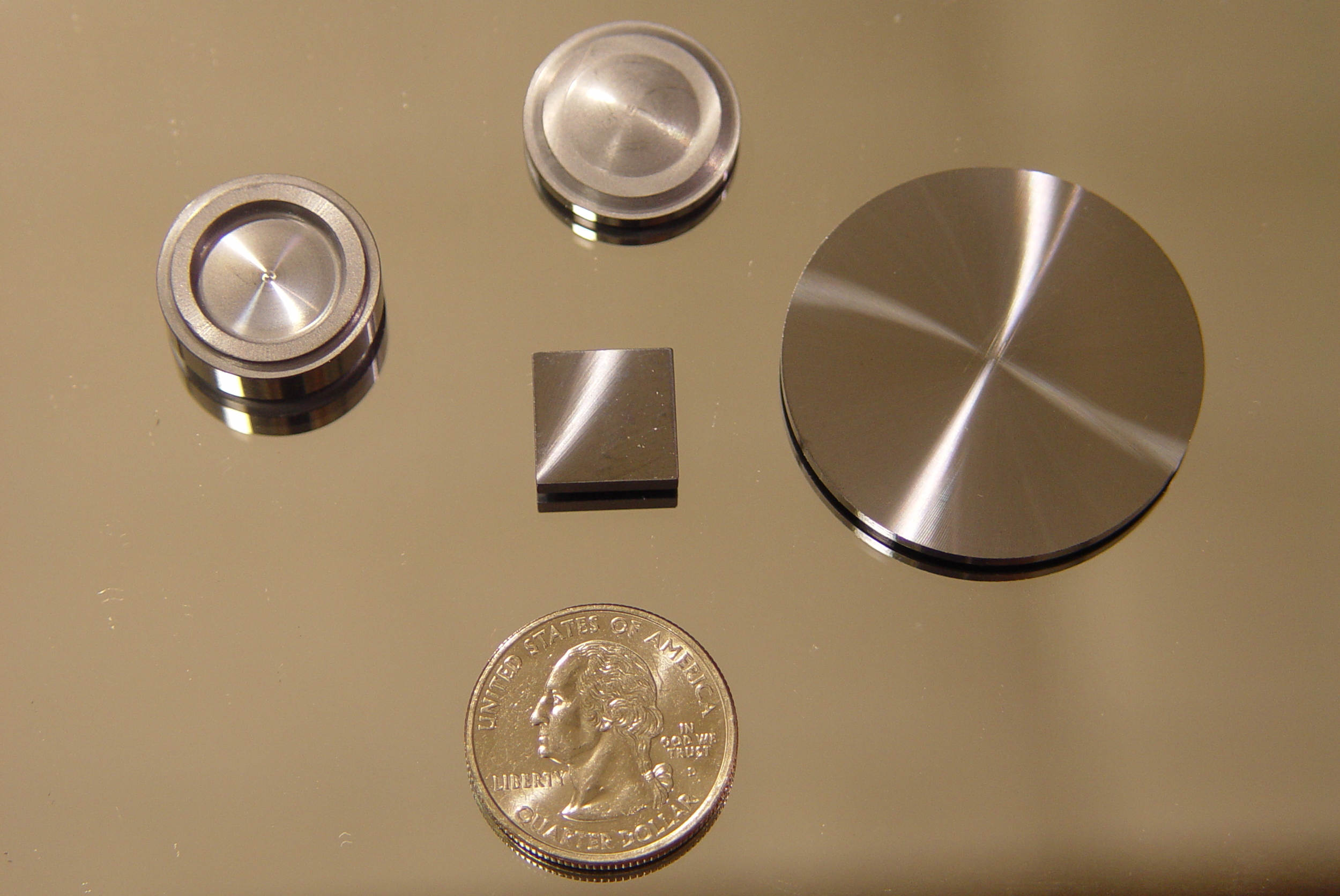

Silicon Optics and Structures

Offering Single Crystal Si as the choice material for optics and optical substrates, even over traditional materials such as beryllium, aluminum, and zerodur, has become a key focus for us.

The perfect cubic structure of Single Crystal Silicon provides the stability and performance required for use as a substitute for Beryllium. Single Crystal Si is used extensively in High Power Laser Optics and has been selected and qualified as the primary MEMS material. Infrared and Midrange Optics can benefit by using Single Crystal Si given that Single Crystal Si has demonstrated stability in dynamic vibration, cryocyling, temporal change, nuclear exposure, coating adhesion, high temperature and pressure survivability. Furthermore, SCSi provides benefits that include low cost by volume, lack of health hazards, low thermal expansion, low density, and high thermal conductivity. SCSi has excellent hardness and shock resistance. All in all, Single Crystal Si provides components with high performance and stability, even in harsh environments, and it is very affordable.

Why Silicon

There are several reasons why Single Crystal Si is a prime candidate for optical components and structures. Single Crystal Si is highly polishable and safe to handle. Also, because of its high thermal conductivity, heat will pass through without absorbing and causing damage. In fact, Single Crystal Si is a stable optic material throughout a wide range of temperature changes from cryo to near 1100°C because it has a high thermal diffusivity, which is a combination of thermal conductivity, specific heat and density properties. In addition, Single Crystal Si is blurr-free during temperature ranging from 170K to 500 C qualifying it as the only optical material that can be used in endo/exo operational missions.

Please note, it is important not to confuse Single Crystal Si with other types of silicon products such as polysilicon, amorphous silicon, silicon foam, and silicon slurry applications. Even though silicon products that are not single crystal are highly polishable, they show deficiencies in several thermal/structural properties.

A detailed description on Single Crystal Si material properties that are relevant to optics are shown in the tables below.