Patented and Proprietary Processes

We fabricate Single Crystal Si structures and optics with near zero surface damage and residual stress, net shaped and ready for optical finishing.

Single Crystal Si is a versatile material that is seeing increased use for mirrors and telescopes. In the past, small boule size and the brittle nature of the material have restricted its applications, but that is no longer the case. Our in-house developed bonding methods allow us to fabricate much larger substrates than available Single Crystal Si boule size.

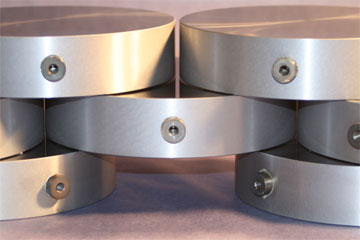

Our patented superfinishing and proprietary frit-bonding processes, along with our experience in machining highly complex and precision silicon components, allows us to offer industry a material that inherently does not creep or jitter — Single Crystal Silicon. We developed and patented a finishing process that allows near

net shaping, thereby drastically reducing or eliminating lapping while maintaining control of the amount of residual surface and subsurface damage. This reduces the time for and complexity of final figuring and produces a stable substrate. Our proprietary frit-bonding process allows for mirrors that are integrated into each other, mounted directly onto metal substrates, built with geometric complexities, and without the

300mm size limitation. In addition, Single Crystal Si mirrors do not need the housings required by other potential Be substitutes. Consequently, the cost, space, and weight are significantly less.

Our expertise with Silicon for Optical structures began with a Silicon Validation Study in 1999. During our internal R&D efforts, our processes were developed and formulations selected specifically customized to the requirements of Single Crystal Si optics and optical substrates.

All but a few of the tests on our Single Crystal Si samples were performed by independent universities and laboratories so that we could quantify and qualify our patented and proprietary processing methods. We now have data on how our processing methods affect SCSi properties in strength, dynamic response, cryostability, coating response, long-term stability, and rad hardness. See Tech Papers for information.